I’d like to tell you about the chemical injection quill, which is a less-common product in the industry, to help users make good plans and technical evaluations.

What is a chemical injection quill?

Chemical injection quill is a piece of machinery used in the chemical injection process, which is used in many different industries. It is a piece of equipment that connects the chemical supply line to the process pipeline. The chemicals that are injected are controlled to cause a chemical reaction, and the quill helps to spread these chemicals through the process pipeline.

Types of applications

Chemical injection is used for many things, like adding additives, treatment with chemicals or biological fluids, and removing or separating things. Here are some examples of chemicals that are used in the process of oil/gas injection:

Methanol

Used to stop hydrates from forming. When hydrate solidifies, it can slow down or stop the flow in wells and flowlines.

Corrosion inhibitors

Used to stop corrosion from happening in wells and pipelines, which cuts down on downtime.

H2S scavenger

Used to treat oil and gas by lowering the amount of H2S to protect health and stop corrosion.

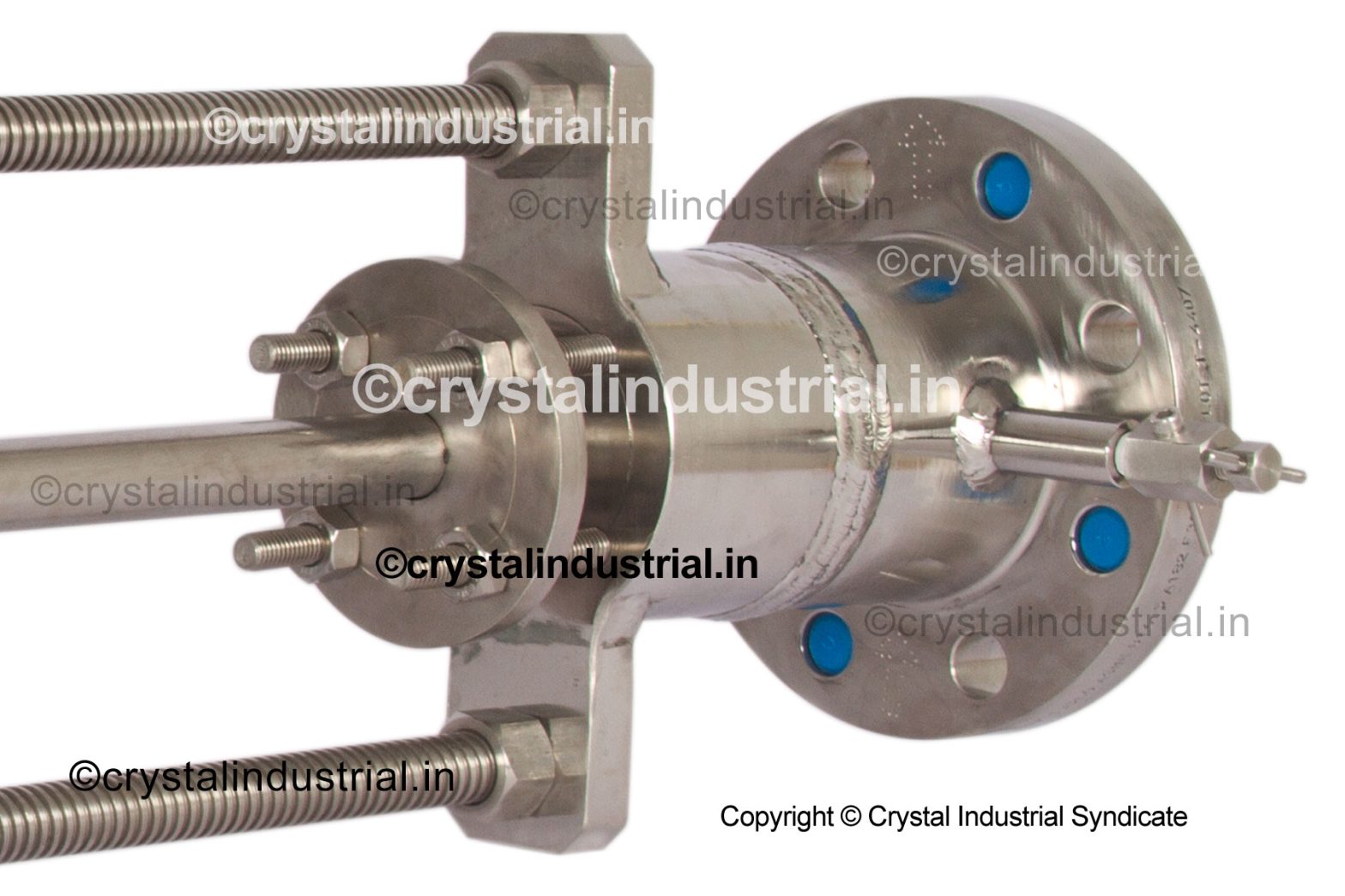

The injection quill could have different shapes, connections, and fittings, such as: From a simple custom-built tube/probe to a single unit with isolation valves and valves that don’t let fluid back in. As part of what we do best, we make an unified chemical injection quill with a probe, double block & bleed assembly ( and 2 isolation valves), and an integral non-return check valve, all in one tight assembly.

This type of quill is attached to the pipeline through a fitting so that the quill or probe can be inserted and reach the middle of the process line. The other end is connected to the chemical feed line by pipes or tubes that go all the way back to the chemical injection skid or chemical Dosing package, which holds the pump and chemical tank.

While an injection quill is designed, the following points must be taken into account:

Design calculation

The wake frequency is calculated using the standard ASME PTC 19.3 TW-2010 for Thermowell, since the quill is very comparable to it. Since the design has to take into account both temperature and stress, the customer should give the necessary process data (fluid, temperature, pressure, velocity, flow rate, density, viscosity). If the calculation isn’t good enough, you can also use a support collar to get a great outcome. A poorly made quill can break quickly and need to be replaced.

Material

The grade of the material should be right for both the service and the type of chemical that will be injected. Since the quill, DBB, and check valve are all part of the same assembly, you need to look at several parameters just like you would for an isolation valve. This includes the body of the valve and its trim, whether it has a soft seat or a metal seat, etc. A bad choice of material grade is the cause of many mechanical problems.

Isolation is safe

There are designs for quills that don’t have an isolation valve built in or that only have a single isolation. In some applications and media, a DBB valve that is built in is important to improve safety. So it is with the Injection Quill, which is installed in API 6A wellheads with a pressure rating of 10,000 psi. When talking about safety, the way the valve seals and how much it leaks are very important. We have a routine customer for injection quills who needs API PSL 3G PR2 because the gas service is very sour. This testing and quality standard is very unique and not something that all manufacturers can meet.

Dimension

The length of the quill is one of the most important things to know when figuring out the wake frequency. Most of the time, the length is made as per custom choice. Most of the time, the chemical is spread out well when the nozzles are in the middle of the pipeline.

Nozzles

The usual tubes or nozzles are used as the standard for the injection quill. But some applications or users need nozzles that are specially made for better atomization.

Options for mounting

There are different ways to mount it. It could be welded, threaded or flanged, depending on the design, but we must make sure that the outside diameter (OD) of the quill or probe will fit all the way down to the process stream. In one case, the outside diameter (O.D.) of the quill or probe did not fit because the welding penetration took into account the small tolerances. Also, threaded connections are usually not the best choice for very high pressure.

If you would like to know how Crystal Industrial Syndicate’s products can support your injection quills requirements, please contact us. We can understand your injection quills requirements and recommend a custom-built solution. Contact us