How do injection quills protect gas pipelines from corrosion

Gas pipelines are an essential part of the energy infrastructure, and it’s crucial to ensure their integrity and longevity. One of the major threats to the integrity of gas pipelines is corrosion, which can cause leaks, explosions, and other hazards. Injection quills are a common method used to protect gas pipelines from corrosion.

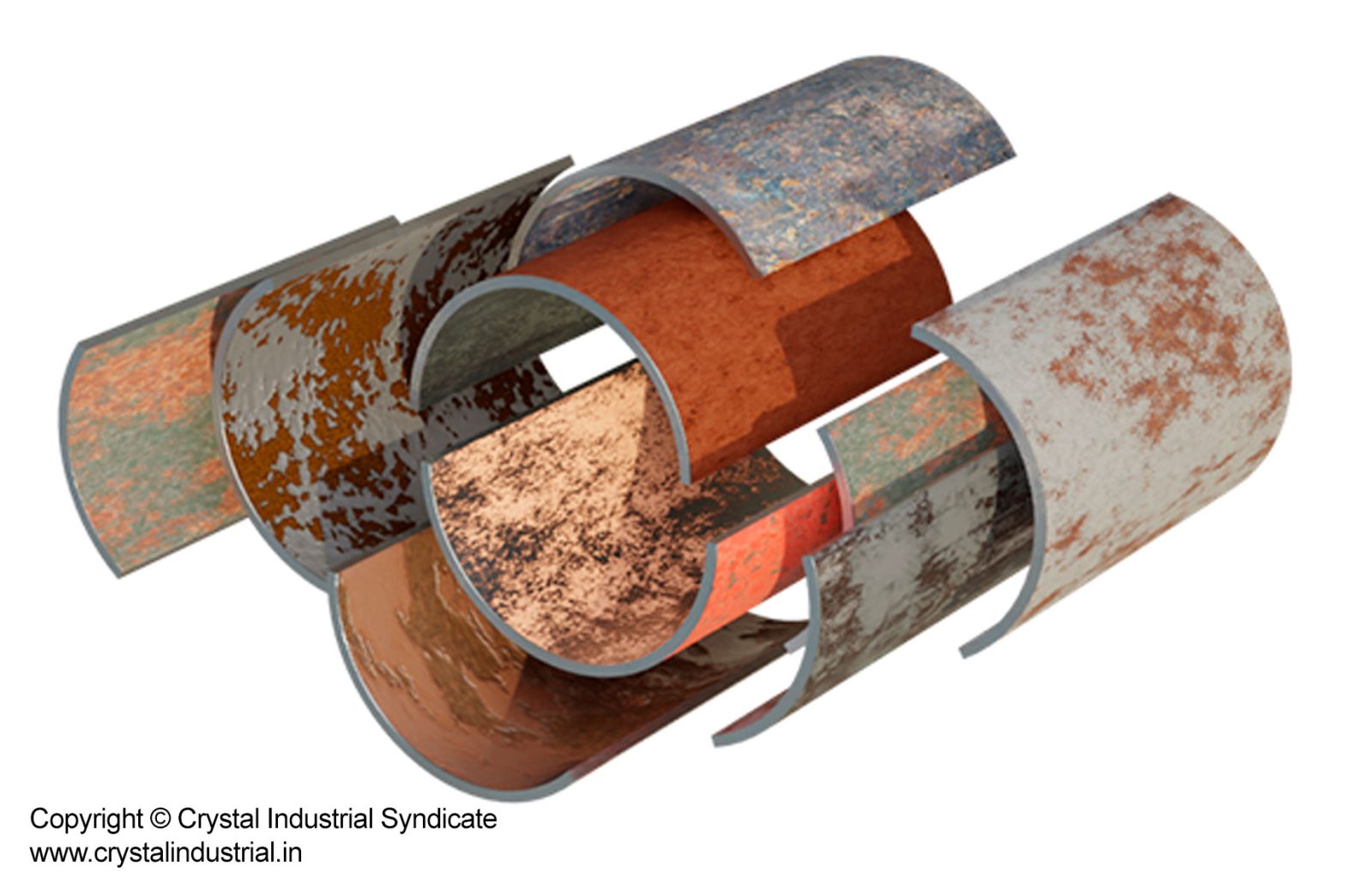

Corrosion occurs when a metal reacts with its environment, leading to the formation of rust or other forms of degradation. In the case of gas pipelines, corrosion can occur due to exposure to water, oxygen, bacteria, and other agents. To prevent this, pipeline operators use corrosion inhibitors, which are chemicals that form a barrier on the surface of the pipe and prevent corrosion-causing agents from coming into contact with the metal.

Injection quills are devices that are installed along the pipeline, which are used to inject corrosion inhibitors into the gas at regular intervals. These quills are typically located near valves, flanges, and other areas where the pipeline is more vulnerable to corrosion. The inhibitors are injected into the pipeline through the quill, where they are carried along by the gas flow and distributed evenly along the pipeline. This helps to ensure that the entire pipeline is protected from corrosion.

There are different types of corrosion inhibitors that can be used, depending on the specific conditions of the pipeline. For example, zinc oxide inhibitors are commonly used in pipelines that transport natural gas, while amine-based inhibitors are often used in pipelines that transport sour gas (gas that contains hydrogen sulfide). Additionally, other types of chemical treatments can also be used, such as biocides, which are used to control the growth of microorganisms that can cause corrosion, and pH adjusters, which are used to control the acidity of the gas.

The use of injection quills helps to ensure that the corrosion inhibitors are distributed evenly along the pipeline, which helps to ensure that the entire pipeline is protected from corrosion. This is particularly important in pipelines that are located in areas where the environment is harsh and corrosive, such as in coastal regions or in areas with high levels of humidity. Additionally, injection quills can also be used to monitor the effectiveness of the corrosion inhibitors, as the operator can analyze samples of the gas to determine the concentration of the inhibitors.

In conclusion, injection quills are an essential tool for protecting gas pipelines from corrosion. They are used to inject corrosion inhibitors into the pipeline at regular intervals, which form a barrier on the surface of the pipe and prevent corrosion-causing agents from coming into contact with the metal. The use of injection quills helps to ensure that the entire pipeline is protected from corrosion, which is crucial for ensuring the integrity and longevity of the pipeline. Additionally, other types of chemical treatments can also be used, such as biocides and pH adjusters, to further protect the pipeline from corrosion.

Why is it important to protect gas pipelines fom corrosion?

It’s important to protect gas pipelines from corrosion for a number of reasons:

- Safety: Corrosion can weaken the structural integrity of a gas pipeline, which can increase the risk of leaks and explosions.

- Environmental impact: Gas pipeline leaks can have serious environmental impacts, including air pollution, soil contamination, and water pollution. Protecting pipelines from corrosion can help reduce the risk of such leaks.

- Maintenance and repair costs: Repairing or replacing a corroded gas pipeline can be expensive and time-consuming. Protecting pipelines from corrosion can help reduce the need for such repairs and the associated costs.

- Reliability: Corrosion can cause gas pipelines to fail or become clogged, which can disrupt the flow of gas and cause service disruptions. Protecting pipelines from corrosion can help ensure reliable gas service.

Overall, protecting gas pipelines from corrosion is important for the safety, environmental health, and reliability of the gas distribution system.

What are the ways to protect gas pipelines from corrosion?

There are several ways to protect gas pipelines from corrosion:

- Coatings: Applying a protective coating to the exterior of the pipeline can help prevent corrosion. There are several types of coatings that can be used, including epoxy coatings, polyurethane coatings, and fusion-bonded epoxy coatings.

- Cathodic protection: This is a technique in which an electrical current is applied to the pipeline to inhibit corrosion. Cathodic protection systems typically involve the use of anodes (electrodes that are more susceptible to corrosion than the pipeline itself) and a rectifier (a device that converts alternating current to direct current).

- Corrosion inhibitors: These are chemicals that are added to the gas in the pipeline to inhibit the corrosion process. There are several types of corrosion inhibitors that can be used, including organic inhibitors, inorganic inhibitors, and mixed inhibitors.

- Materials selection: Choosing corrosion-resistant materials for the construction of the pipeline can help prevent corrosion. Stainless steel, aluminum, and some types of plastic are examples of materials that are resistant to corrosion.

- Pipeline design: The design of the pipeline can also impact its susceptibility to corrosion. Factors such as the pipeline’s diameter, wall thickness, and the type of soil it is buried in can all affect corrosion rates.

It’s worth noting that no single method is likely to be completely effective at preventing corrosion in a gas pipeline. Therefore, it is usually necessary to use a combination of these methods to adequately protect the pipeline.

Crystal Industrial Syndicate from India, makes a range of custom injection quills for a variety of industrial processes. Our injection quills are manufactured in India and comply with the world’s most stringent certifications. Our products are installed around the world, from North America and Europe to Africa and the Middle East. Contact us to know more about how we can support your injection quills requirements. Contact us

Copyright © 2023 by Crystal Industrial Syndicate Pvt Ltd. All rights reserved. www.crystalindustrial.in